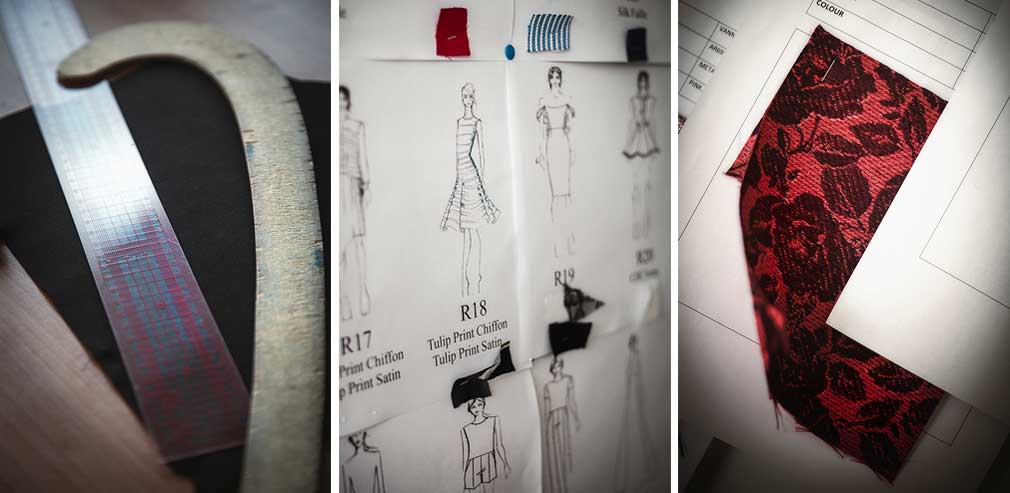

Pattern Making & Prototyping

The RWE atelier is the heart of our business. Here the magic begins and the visions of our clientele are brought to life.

We are excited to work collaboratively receiving sketches from our clients where an initial handover sees an intertwining of ideas, problem solving and thinking out of the box solutions.

From first pattern and muslin to fittings and prototyping, artisanship and technology combine to deliver top quality result within established time frames. Patternmaker and seamstress work hand in glove to meticulously fit and aesthetically translate the original idea.

Sourcing and Research

Every season at RWE, we partner with our customers to propose new and exciting methods of garment engineering.

We offer services for material and trim sourcing, keeping up to date with new and specialised workmanship some of which include double face, laser cutting, pleating, hand made stitches, embroidery, paillettes, drapings, handmade tailored canvas. While we nurture our people and their training, we balance this with investment in technology that can elevate the engineering of our garments.

Sampling

Once a final prototype has been approved, we move into the transformative stage of sampling. New material combinations, perfected execution, attention to detailing and a finesse of fit, all blend to create exceptional garments for international catwalks and showrooms.